From Tracks to Rollers: Checking Out a Large Range of Komatsu Undercarriage Parts

From Tracks to Rollers: Checking Out a Large Range of Komatsu Undercarriage Parts

Blog Article

Boost Efficiency With Undercarriage Components and Its Utilizes

Recognizing the complex components that compose the undercarriage of hefty machinery is crucial for companies intending to enhance their functional efficiency. From track shoes to idlers and sprockets, undercarriage components play a crucial role in the performance and long life of devices. The critical utilization of these elements can result in considerable enhancements in performance and cost savings. Allow's discover how companies can harness the power of undercarriage parts to streamline their procedures and drive success in an affordable market.

Significance of Undercarriage Components

Regular upkeep and timely replacement of undercarriage parts are essential to avoid pricey downtime and make the most of performance. Worn-out undercarriage parts can bring about reduced grip, enhanced gas intake, and accelerated wear on other parts of the machinery. By investing in top notch undercarriage parts and sticking to a rigorous upkeep schedule, drivers can optimize the efficiency of their heavy equipment and expand its life span.

Common Sorts Of Undercarriage Parts

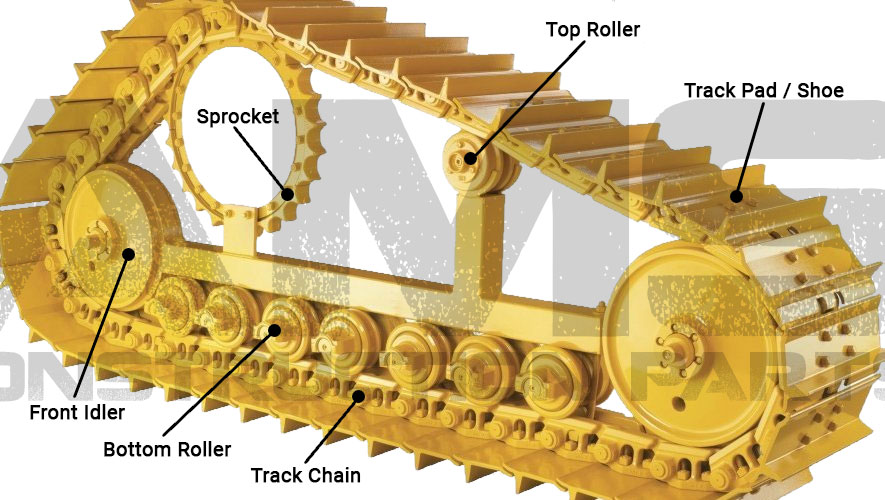

Crucial components important for the reliable operation of hefty machinery, undercarriage components play a vital function in making certain optimum performance and longevity of the tools. Some common kinds of undercarriage parts consist of track chains, track footwear, rollers, idlers, gears, and track frames. Understanding the function and importance of these typical undercarriage components is necessary for keeping hefty equipment in optimum functioning problem, reducing downtime, and taking full advantage of efficiency on job websites.

Advantages of Regular Maintenance

Enhancing functional efficiency and extending devices life-span, regular maintenance of undercarriage components is pivotal for maximizing hefty equipment performance. By sticking to a structured upkeep timetable, drivers can avoid expensive breakdowns and minimize downtime. Normal assessments and servicing of undercarriage parts such as tracks, rollers, gears, and idlers not just make certain smooth operation yet additionally add to general security on task sites.

Enhancing Tools Efficiency

In addition, choosing the ideal check my blog undercarriage components for details operating conditions is critical. When choosing undercarriage components, aspects such as the kind of surface, work, and ecological problems should be taken into consideration. Making use of top notch components that are created to hold up against the needs of the work can enhance general tools efficiency and longevity.

Additionally, keeping undercarriage parts clean and well-lubricated is essential for smooth procedure. Dust, debris, and lack of lubrication can cause early damage on parts, resulting in minimized efficiency and prospective failures. Normal cleansing and lubrication regimens can help stop these concerns and guarantee constant tools efficiency.

Cost-Effective Solutions for Organizations

To enhance undercarriage parts effectively and ensure long-lasting equipment performance, organizations need to prioritize affordable services that straighten with their operational demands and budget plan constraints (komatsu undercarriage parts). Investing in top notch undercarriage components can lead to significant cost savings in the lengthy run by lowering downtime, upkeep costs, and the danger of unanticipated equipment failings.

Additionally, organizations can discover different undercarriage parts such as aftermarket elements that meet market standards and specifications at a reduced cost than OEM components. By meticulously examining their alternatives and partnering with reputable distributors, companies can effectively manage their undercarriage part expenditures without compromising on efficiency or reliability.

Verdict

To conclude, undercarriage components play a critical duty in enhancing equipment efficiency and performance. Normal maintenance of these parts is essential to make sure smooth procedure and stop costly breakdowns. By buying high quality undercarriage parts and executing a proactive upkeep schedule, companies can enhance performance, minimize downtime, and ultimately save money on costs. It is clear that undercarriage components are important components for organizations wanting to boost performance and preserve their tools in optimum condition.

From track footwear to idlers and gears, undercarriage components play an important you could try here role in the performance and long life of tools.The significance of undercarriage parts in heavy machinery can not be overemphasized, as they are necessary components that substantially impact the general efficiency and longevity of the devices.Essential parts necessary for the efficient operation of hefty equipment, undercarriage components play a crucial function in guaranteeing optimal efficiency and durability of the equipment.Enhancing operational effectiveness and prolonging devices life-span, routine maintenance of undercarriage components is pivotal for optimizing hefty machinery efficiency. Additionally, companies can discover alternative undercarriage components such as aftermarket elements that meet sector standards and specifications at a reduced price than OEM components.

Report this page